Replacing screws

There are certain screws on your telescope that need to be adjusted from time to time. So it’s important that their operation and quality match your expectations.

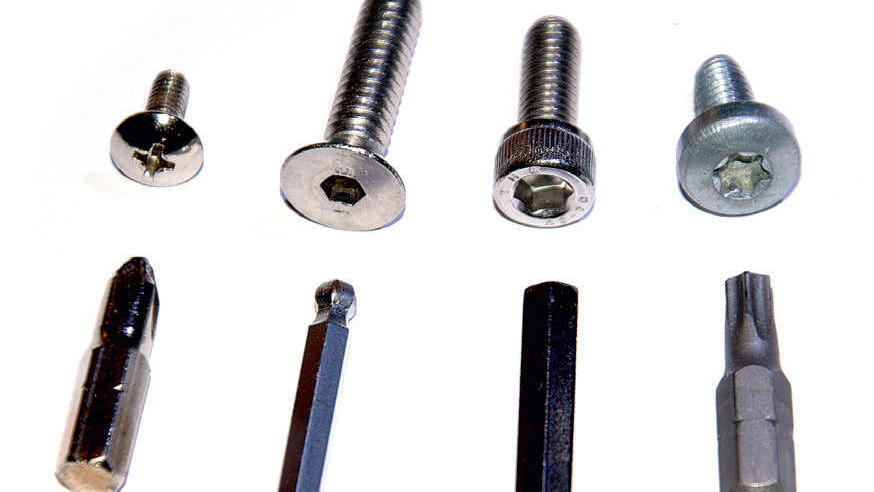

Allen (center) and Torx (right) screws absorb high torque and prevent your screwdriver from accidentally slipping. S. Wienstein

Allen (center) and Torx (right) screws absorb high torque and prevent your screwdriver from accidentally slipping. S. WiensteinWhile most screws are tightened once and do not need to be re-adjusted, there are a number of screws on a telescope that are constantly in motion. Where this is the case, we expect smooth operation and good quality.

Our humid climate corrodes screws over time, and the screw will start to rust once the normal zinc coating has gone. This is not a purely cosmetic problem, because rust can permanently settle on optical surfaces. We recommend stainless steel or, in the case of thumb screws and depending on the load they are subjected to, a hard brass alloy.

Screws that are too soft are particularly annoying, and it is not only cross-head screws and slotted screws that can become stripped. If this starts to happen, they should be replaced urgently, long before you find that your screwdriver can no longer turn them. When chosing replacements you should consider Allen or Torx screws. In general, it is much easier to adjust a screw with an Allen key than with a cross-head or flat-head screwdriver. Thumb screws are even more user-friendly, and these can also be turned with a key if they get too tight.

By the way: clamping screws do not need to leave ugly marks on barrels or prism rails. They can be replaced with screws with a plastic or rubber tip, or even screws made entirely of plastic. If this does not work, you can round off the screw tip with a file and sandpaper. But be careful: if the screw is only coated, it will later start to rust.

Author: Sven Wienstein / Licence: Oculum Verlag GmbH